Specialty & Industrial Packaging Solutions

Precision stamping and forming ensure boxes meet specs.

1500+ clients

Appearance, dimensional, durability tests ensure lasting safety.

What is Specialty Industrial Metal Packaging

Specialty industrial metal packaging refers to robust, precision-formed tin or steel containers designed specifically for equipment, components, and industrial-grade materials.

Unlike traditional consumer packaging, these metal boxes feature reinforced structures, high-impact resistance, and protective surface finishes to withstand harsh handling and environmental conditions.

Their engineered form allows the packaging to secure critical components, prevent damage, and maintain product integrity while offering excellent longevity and reusability.

Industrial Metal Packaging Structure and Application

Industrial metal packaging is typically manufactured using high-strength tinplate or steel sheets, combined with precision stamping and forming processes. The exterior can be customized with protective coatings, anti-corrosion layers, or enhanced surface treatments. Inner components may include EVA foam inserts, partitions, or fitted trays to secure items.

Depending on application needs, internal linings can incorporate anti-scratching materials, moisture-resistant layers, or anti-static structures. Because the metal body offers rigidity and impact resistance, industrial tins provide stable protection without distortion during transport.

Meanwhile, the multi-layer structural options — such as reinforced walls or double-seam edges — allow for stronger load-bearing capacity while reducing the need for excessive packaging materials, lowering weight, and saving space during logistics.

Discover Our Custom Industrial Metal Boxes and Components

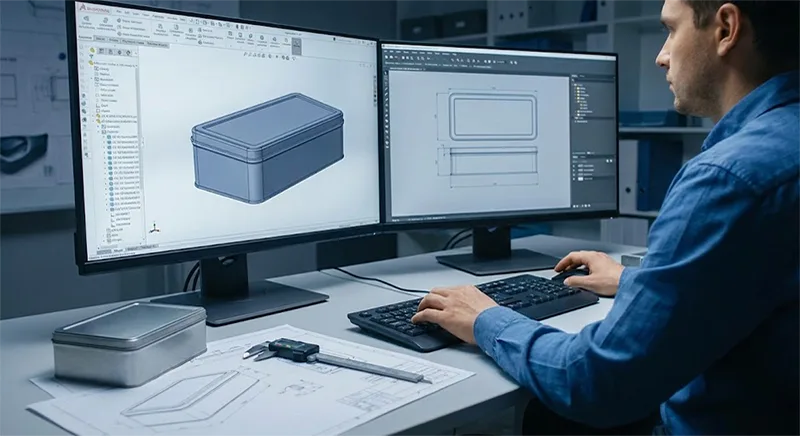

How We Create Your Custom Metal Packaging

Step 1 — Consultation & Requirements

Step 2 — 3D Drawing & Structure Design

Step 3 — Mold Development or Sample Making

Step 4 — Printing & Surface Finishing

Step 5 — Stamping & Assembly Process

Step 6 — Quality Inspection & Packaging