Food & Beverage Metal Packaging Solutions

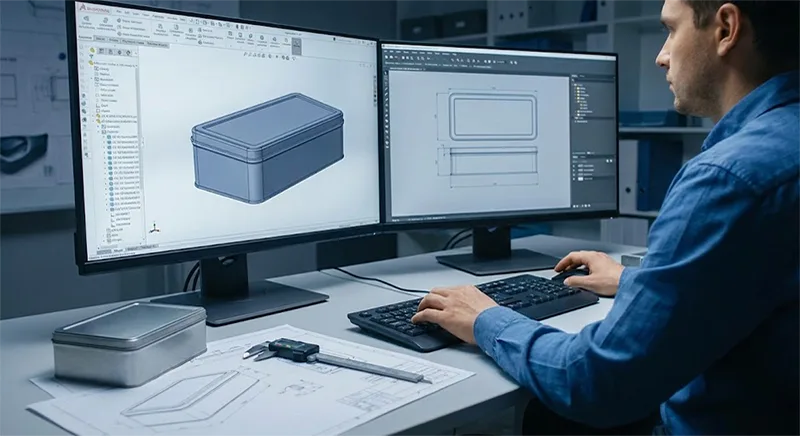

Precision stamping and forming ensure boxes meet specs.

1500+ clients

Appearance, dimensional, durability tests ensure lasting safety.

What is Food & Beverage Metal Packaging

Food & beverage metal packaging refers to food-grade tin boxes and metal containers designed specifically to protect snacks, tea, coffee, chocolates, candies, and specialty food products.

These metal packages are crafted using high-quality tinplate through precision stamping and forming, ensuring airtightness, durability, and safe contact with food products.

The inherent strength and barrier properties of metal packaging help block light, moisture, oxygen, and contamination — maintaining product freshness, flavor, and shelf appeal for extended periods.

Food & Beverage Metal Packaging Structure and Application

Food-grade metal packaging is produced using high-quality tinplate sheets formed through multi-stage stamping, followed by precise edge curling and seamless assembly. The inner coating typically includes food-safe lacquer layers such as epoxy or BPA-free alternatives to prevent corrosion and ensure product compatibility.

The exterior surface can be customized with premium printing, embossing, matte, glossy, or textured finishes. With strong structural rigidity and excellent barrier performance, metal food packaging resists deformation, protects contents, and maintains a premium appearance throughout distribution.

At the same time, the recyclable and reusable nature of tinplate makes metal packaging an environmentally friendly solution that reduces waste, supports sustainability goals, and enhances brand perception in modern retail.

Discover Our Custom Food & Beverage Metal Packaging

How We Create Your Custom Metal Packaging

Step 1 — Consultation & Requirements

Step 2 — 3D Drawing & Structure Design

Step 3 — Mold Development or Sample Making

Step 4 — Printing & Surface Finishing

Step 5 — Stamping & Assembly Process

Step 6 — Quality Inspection & Packaging