Beauty & Personal Care Packaging Solutions

Precision stamping and forming ensure boxes meet specs.

1500+ clients

Appearance, dimensional, durability tests ensure lasting safety.

What Is Beauty & Personal Care Metal Packaging

Beauty & personal care metal packaging refers to custom-engineered tin boxes or metal containers designed specifically for cosmetics, skincare, fragrances, and personal care items.

These packages are crafted using food-safe, corrosion-resistant tinplate or aluminum, formed through precision stamping and shaping to achieve premium aesthetics and functional protection.

This advanced structure enhances impact resistance, supports luxurious visual finishes, and enables numerous shapes, sizes, and decorative effects—allowing brands to deliver both beauty and durability in a wide range of applications.

Beauty & Personal Care Packaging Structure and Application

Beauty and personal care tin packaging is formed from high-quality tinplate sheets through multi-step stamping processes, with the exterior finished using custom printing, embossing, or surface treatments. The inner structure can include optional liners, coatings, or inserts to protect delicate cosmetic formulas and ensure product safety.

Surface finishes typically include glossy varnish, matte coating, pearl textures, or specialty spot effects. These finishes—combined with corrosion-resistant materials—ensure long-lasting appearance and stability. The smooth interior and precise fit design allow containers to open and close effortlessly while maintaining tight sealing.

At the same time, the customizable shapes, lightweight structure, and high durability of metal packaging provide strong protection for creams, balms, soaps, solid fragrances, beauty tools, and gift sets—reducing breakage, improving shelf impact, and saving space during transportation.

Discover Our Custom Beauty & Personal Care Packaging

How We Create Your Custom Metal Packaging

Step 1 — Consultation & Requirements

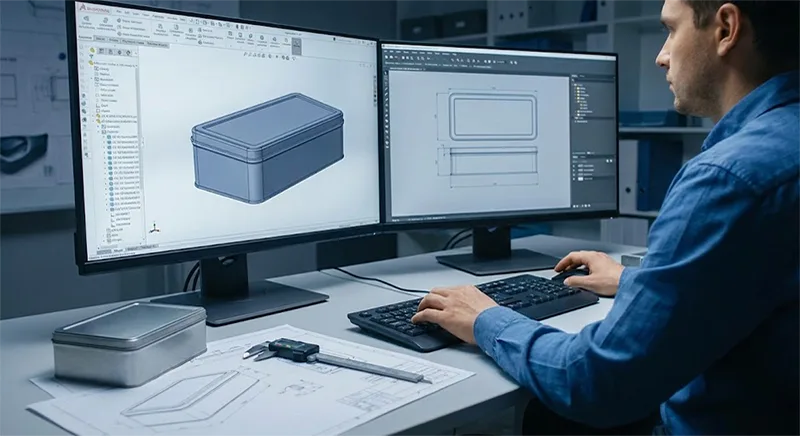

Step 2 — 3D Drawing & Structure Design

Step 3 — Mold Development or Sample Making

Step 4 — Printing & Surface Finishing

Step 5 — Stamping & Assembly Process

Step 6 — Quality Inspection & Packaging